The fireplace is made of brick angular: order, review of corner models and design features. Laying ovens with their own hands schemes

03.08.2017

468

Pechnik (Moscow)

The fireplace is made of brick angular, has a number of distinctive features and is universal. Such a heating unit can be installed both in a fairly spacious two-story house and in a small country house.

Corner stove fireplace made of brick with a fairly small size and average weight, does not take up much space and at the same time is able to act as the main source of heating.

In this article, you can familiarize yourself with the simplest ordering-layout, learn more about its design features and view the rating of the best purchased corner metal foci. Selected photos will help you in visual introduction.

Rating of purchased metal foci

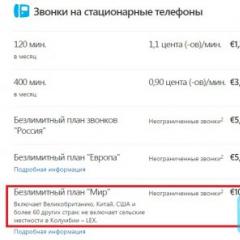

An angular brick fireplace stove is distinguished by a rather complicated assembly and installation; the ready-made metal foci are the simplest. In this table you can learn more about the most inexpensive and popular models to date:

|

Descriptions and specifications |

|

|

Bavaria corner

|

The installation of such a hearth is quite possible with their own hands. The body of the fireplace is made of steel, whose thickness is six millimeters. The inner part of the installation is lined with fireclay bricks. The sides are made of ceramic, and the power of the heating unit is 6 kilowatts, which allows you to heat the house, with a total area of up to 50 square meters. |

|

|

The model is based on a small fireproof panoramic glass. The design itself is equipped with a small cooking surface for cooking on two burners. A power of nine kilowatts allows heating the house, the footage of which is about 170 cubic meters. The sidewalls of the model are also lined with refractory ceramics panels, which significantly increases the efficiency and heat transfer of the hearth. |

|

|

The instruction to this model indicates the possibility simple use. Such a firebox has a power of 6 kilowatts, which allows you to evenly heat the space with a total area of up to 50 squares. Additionally, the fireplace is covered with heat-resistant paint, which significantly prolongs its service life and does not allow rust and corrosion to form. |

|

Teplodar

|

One of the most powerful combustion chambers, 12 kilowatts. Such a heating unit is suitable for buildings with a meter up to 70-80 square meters. For the design of the door is used refractory glass ceramics. The main part of the construction is made of stainless steel. |

It is interesting to know: the metal purchase center, is distinguished by its high efficiency, affordable cost, simple installation. For such installations there is no need to assemble an additional foundation, and installation is possible on any floor and floor, as the firebox has small dimensions and weight. The design itself can be carried out in any style and have a number of additional functions, for example, long-term burning or self-cleaning of the refractory glass with which the door is equipped.

In order to learn more about the models presented in the table, we recommend also to watch the video in this article.

Design features of corner brick fireplaces

Fireplaces made of corner brick, as well as metal foci, have a number of their design features and advantages:

- Fireplaces corner of brick require a lot of time for the construction of the foundation, the choice of a suitable and professionally made order;

- Assembly and laying may also differ;

- For the assembly of each element of construction it is necessary to use a certain type of brick;

- The finished unit is distinguished by its high heat capacity and at least good heat dissipation;

- The fireplace cools down for a long time and continues to give off heat even at the end of the firebox;

- Corner brick fireplaces can be of various shapes, sizes, and also later be revetted with any refractory materials and coatings (tiles, ceramic tiles, artificial and natural stone, decorative plaster);

- The coating is distinguished by its environmental friendliness and durability. Such installations are not prone to burning, abrasion, deformation;

- The capacity of the furnace is determined individually and depends on the size, area of the house, its height;

- A corner brick fireplace, despite the high heating temperatures in the inner part of the firebox, is notable for its safety, since its external surfaces remain warm and it is simply impossible to burn about them.

Tip: for proper assembly and correct operation of the heating unit, you will definitely need drawings of corner fireplaces made of bricks. If you have no experience in the preparation of such projects, at this stage it is best to seek professional help. Only a specialist will be able to say exactly what kind of power, location and dimensions of the structure will be optimal and suitable in your particular case.

Preparatory work

In order to assemble a brick corner fireplace, you must perform a detailed drawing and select the optimal place for installation, after which the calculation of all building materials, accessories and fasteners should be made. For the assembly and construction of the corner structure we need:

- Red brick brand M-100 (about 750 pieces, the material for the assembly of the chimney is calculated separately);

- Chamotte brick 50 pieces;

- A strip of steel measuring 600 by 300 by 3 millimeters;

- Steel angle of 100 to 100 millimeters, L = 750 millimeters;

- Two steel sheets measuring 300 by 300 by 3 and 530 by 400 and 3 millimeters;

- Sand and clay (0.5 and 0.8 cubic meters, excluding the chimney);

- Blower and firebox (140x250 and 210x250 millimeters);

- Two clean doors with dimensions of 140 by 130 millimeters;

- One hob and oven (410x410 and 300x280x510);

- Oven and chimney valve (130 to 250 and 250 to 250 millimeters).

It is interesting to know: an angular brick fireplace assembled according to this scheme of Grigoriev has two fireboxes, one of which is a fireplace, and the second is a stove. The furnace chamber is turned to the side, while the fireplace room is located in the center. The overall dimensions of the heating unit are 127 to 89 centimeters. If desired, you can use separately a stove or fireplace, and both combustion chambers at the same time.

Foundation building

Since the corner brick fireplace has a sufficiently large mass, for its installation, it is necessary to assemble a separate foundation. At this stage, we recommend using the following step-by-step tutorials and tips:

- The most reliable foundation is monolithic reinforced. The length of the foundation should be 8-13 centimeters longer than the fireplace on both sides;

- At the first stage, the marking is performed, after which a hole of the corresponding size is dug out;

- For a small house, the depth of the pit may be about 50 centimeters (tape);

Important: never combine the foundations of the fireplace and the house between them. This can lead to destruction!

- The first layer is filled with sand, its layer is 8-12 centimeters, after which water is poured from above, and the layer is well compacted;

- Next is the formwork. For this purpose boards are used, the thickness of which is 20-25 millimeters. Alternatively, you can use plywood. The formwork can be either completely airtight or removable;

- Further, the bars of the bars fit the grid size of fifteen to fifteen centimeters. The rods are connected by wire, in places where they intersect with each other;

- If the height of the foundation is more than 18 centimeters, the reinforcement is placed twice in the upper and lower parts;

- Next, a cement based mortar is prepared. At a ratio of 1: 2: 2 (cement to rubble and river sand). Water is added, so that the consistency is of medium density;

- The concrete mix is poured into the formwork at one time (completely), in a large layer;

- The foundation itself must be below the floor level by an average of 9-18 centimeters.

Important: at the end of the work, cover the foundation with a transparent film and let it completely harden and level. It will take from 2 to 6 days.

Corner fireplace

Fireplace brick corner, requires the correct order, which directly depends on the quality of the work of traction, safety of use and durability of the heating unit.

To build, use the following ordering scheme:

- The corner brick fireplace is laid out as follows: before proceeding with the laying of bricks on cement, the fitting is done to dry. All broken and crushed bricks are immediately eliminated. Suitable bricks are soaked in water;

Tip: Corner brick fireplace stacked on a different composition. For the front rows, this is a cement based compound. For subsequent work, you will need a bonding composition, which is based on refractory clay.

- With full-body bricks on a ceramic base, the two rows are laid out in such a way that the foundation reaches the level of the floor;

- Two subsequent rows are laid out with ceramics. At this stage is formed under the fireplace. When doing klaki brick is cut off;

- The third row forms the initial components of the ash pan and the combustion chamber of the stove. The door is installed on pre-fixed metal rods, if necessary, these fasteners can be replaced with nails;

- 4 row allows you to perform additional fastening of doors and firebox with the use of wire. After that, fasteners are sealed in a laying at a depth of about 25-30 centimeters. For stacking the next row, on top of the firebox and the door, metal fittings are laid and fixed;

- The fifth row allows the doors to be closed, after which a dividing steel strip is placed on 6;

- From the seventh to the ninth row laid out a fireplace insert. The door is fixed with metal plates. In the rear part of the furnace opening, a toothed element begins to form (a wall having a bevel);

- 10 row is characterized by the transition to the smoke channel. On the eleventh you need to install and fix the hob. For laying stoves need to apply only heat-resistant solution. This element is tried on directly on the firebox, after which a row of bricks is laid dry, which is numbered and disassembled. Grinders drilled grooves. Then a strip of steel is laid, after which we continue to lay the tooth of the fireplace;

- In the twelfth row, fireclay bricks enclose the overlap of the fire chamber of the fireplace, and smoke exhaust channels similarly overlap. In the place where the furnace hole and hob, stack only the sidewall (rear side); Corner pentahedral stove with a hob

- Brick corner fireplaces assembled according to this scheme, from the fourteenth to the eighteenth row form an expanded smoke box, smoke channels and a wall near the camphor tile;

- On the 16, 17 rows laid out a mantel shelf. The nineteenth row is covered with a metal sheet, and on the twentieth and twenty-first it is shifted with bricks;

- Further, smoke exhaust channels and a collection of smoke continues to be laid on the side of the fireplace. At 22, 23, the smoke channels begin to expand, a cleaning door is being installed. For the twenty-fourth row, a cut-off installation is typical, and the back of the smoke box is equipped with a metal strip;

- The following 2 rows fit in the standard way. On the 27th row a plug is installed, and on the 28th a clean door. Further the sheet of metal keeps within, and from the thirtieth to the thirty second row the brick lays down according to the standard scheme;

- At 33, thirty-fourth rows overlaps the fireplace smoke channel, the thirty-fifth is characterized by the assembly of a decorative side. With 36 rows begins laying chimney. The brick is shifted, after which the rows are tied up.

Corner pentahedral stove with a hob

Fireplaces brick corner collected by this ordering, are small in size, convenient placement and high power.

The stove fireplace from a brick corner will fit perfectly into a house with any number of floors and area. Despite the complexity of assembly and installation, this design is characterized by high power, efficiency, good heat dissipation, durability and minimal wear rate, even with daily use.

At a time when the stationary solid-fuel stove was the only existing means of heating a house, the stove profession was very popular and respected. To date, for arranging individual heating, you can use a variety of different units that operate on the most diverse fuels, however, brick ovens still remain in demand.

Currently, finding a truly competent stove-maker is not an easy task. Yes, and do not need to do this, because you can lay out a full-fledged stove with your own hands.

Before embarking on self-laying stove familiarize yourself with the features of existing varieties of such units. Stoves are:

- heating Designed exclusively for heating. Such furnaces have an extremely simple design and are laid out in the shortest possible time and with the least effort compared to structures of other types;

- heating and cooking. The most popular and popular option. At the same time heat the house and allow you to cook;

There are also improved varieties of heating and cooking stoves with built-in cooking stove or even a full oven.

In a separate category are stoves. This is a great option for a modern private house. Such constructions perfectly cope with the tasks of space heating and have an attractive appearance. Properly laid out and decorated stove-fireplace will be a worthy addition to the interior of a small country house and an expensive private villa.

The schemes of modern furnaces distinguish them not only according to their intended purpose, but also according to the peculiarities of their form. Most often, in private houses are installed units of rectangular and square shape. But if you wish, you can lay out a round oven. Choose a specific option, taking into account the characteristics of the room and your own preferences.

The furnace, of course, can be laid out with your own hands and numerous schemes will help you to do this in the shortest possible time. However, when performing such work, remember that any furnace, regardless of its purpose, shape and other characteristics, must fully comply with current fire safety regulations.

Choosing the location and type of foundation for the stove

Before you start laying the furnace, pay due attention to finding a place to place it. For example, if the unit is placed in the middle of a room, it will be able to give much more heat, warming itself from all sides and heating the air around it evenly.

If the stove is placed against the wall (and this option is used most often), cold air will constantly “walk” around the floor. Therefore, in this regard, you need to make a decision on your own.

Pre-determine the installation location of the furnace door. This element must be installed so that in the future you can conveniently and quickly load fuel into the stove, without carrying the trash of firewood or coal throughout the house. Usually the furnace door is located on the side of the kitchen or some obscure premises.

The finished brick stove will have a rather impressive weight. For the device to stand as reliably and as long as possible, it is necessary to prepare an individual concrete foundation for it.

Features of the furnace design

Traditional brick kilns have a fairly simple design. However, the seeming simplicity at first glance makes it possible to achieve very high rates of productivity and efficiency.

The main elements of the brick furnace body are the firebox and the chimney. Cooking stoves are additionally completed with stoves and / or ovens, it is also possible to install a tank for heating water.

The firelighter is the main part of the furnace unit. Firewood or other fuel used for heating is loaded into the firebox. A fireman can have a wide variety of sizes. In determining the appropriate dimensions, several important factors need to be considered, such as:

- type of fuel used. If you burn wood with a stove, make a firebox 50-100 cm high;

- required performance;

- required volume.

For the arrangement of the firebox, use a fireproof brick. The wall thickness of the structure under consideration cannot be less than half of the brick.

The chimney is also among the main elements of any heating furnace. The chimney is designed to discharge flue gases with various harmful inclusions formed during the operation of the furnace.

At the design stage of the chimney, try to think everything over so that its design has the minimum number of twists and turns. Ideally, the chimney should be completely vertical. Any kind of bending will lead to a deterioration of traction and reduce the efficiency of space heating.

The ash pan chamber is one of the important elements of the brick kiln design. In this compartment will be collected ash. Also through the ash pan air is supplied to the inside of the unit, to the fuel. The ash chamber settles down under the grate grate and is supplied with its own door. Traditionally, the height of the ashpit is 3 bricks.

What mortar should be used for masonry?

Reliability and durability of the finished furnace directly depends on the quality of the masonry mortar. Masonry will be conducted using a mortar on a sandy-clay base.

In the preparation of the solution is nothing complicated. Take the clay, cover it with water and soak it. Sift the mixture through a sieve, and then stir it into “earthen milk.” Finally, add some water to get a sufficiently viscous and plastic solution.

Remember, the reliability and durability of the furnace directly depends on the correct preparation of the masonry mortar. Do everything as it should - the stove will effectively heat your house for many years. Break the technology or decide to save a lot on materials - the heating unit is unlikely to be able to reach its full potential and stand for any length of time.

The main stages and important features of the laying of the furnace

It takes 3-4 weeks from the moment of the foundation filling to the start of construction. During this time, the base will gain the necessary strength and will be able to withstand the weight of the brick kiln. The work in question requires maximum responsibility and concentration on the part of the performer. Any mistakes can lead to irreparable consequences, so tune in to work in advance and set aside enough time to complete it.

The laying of the furnace is carried out in several stages.

First stage. Lay out the ash pan and the lower part of the first cap of the brick. Laying should be carried out using the previously considered sand-clay solution.

Second phase. Install the ash pan door in the masonry. To fix the door, use galvanized wire.

The third stage.

Fourth stage. Mount the firebox. Cover the inside of this compartment with fireproof brick. Bricks lay out "on the edge." At this stage, you need to use a special masonry mortar. It is prepared as standard, but instead of simple clay, fireproof is taken, i.e. fireclay. Secure the furnace chamber door with a steel plate and wire you already know.

Fifth stage. Continue to the standard clutch until you reach the 12th row. After reaching this row, turn off the combustion chamber and smoothly lay the tile with the burners. This plate should be made of cast iron. Check the leveling of the paving using the building level.

The sixth stage. Lay out the first cap. It is built in the left edge of the stove. At the same stage, the channel for the summer course is being settled.

Seventh stage. Install the stove and lay the walls of the cooking compartment. Maintain the aforementioned lower cap.

The eighth stage. Install the valve for the mentioned summer run channel. This valve is located in the inner corner of the cooking compartment.

The ninth stage. Keep laying up to the 20th row. After reaching this row, turn off the cooking compartment and the first cap. Be sure to leave in the solid laying the required number of holes for the summer course and the lifting channel, as well as the vent of the cooking compartment. Place the bricks on the corners of steel - so you will provide a higher strength and reliability of the stove.

The tenth stage. Close the brewhouse portal with hinged fire doors. It is better that the doors had heat-resistant glass inserts. Such a solution will allow you to monitor the process of burning fuel and admire the flame.

Eleventh stage. Install cleaning doors for easy removal of soot. To install, choose a place that you will be the easiest to get to.

The twelfth stage. Lay the cap walls almost to the top edge of the wall opening. At the top, turn off the stove with a pair of rows of bricks. Fill the gap between the top of the stove and the bridge. This will provide additional thermal insulation and slightly increase the heating efficiency.

Thirteenth stage. Lay out a decorative belt on the upper perimeter of the unit.

Fourteenth stage. Proceed to the device chimney. It is better that the chimney was brick. This design will last much longer than the same metal or asbestos pipes.

In the end, all you have to do is to lay out the chimney to the end and, if desired, complete the external finish of the stove. The simplest option is plastering. For the rest, be guided by your own preferences and affordable budget.

Thus, laying the stove, though not a simple event, but it is quite possible to do it yourself. It is enough just to understand the technology and follow the instructions. Remember, materials for work must be of the highest quality. And proven for years, the scheme of the furnaces will allow you to build your own unit, which for many years will qualitatively heat your home without any problems and complaints.

Have a good job!

Video - Laying furnaces do-it-yourself schemes

Competently laid out corner brick fireplace will be a great addition to almost any interior. In this case, the unit will fully cope with the solution of problems of heating the premises. With the laying of the fireplace you can cope on your own. See further recommendations and get to work.

To accommodate a corner fireplace, you can choose a place both near the outside of the wall and near its inside. The most important thing is to determine the optimal order of installation of the pipe for the discharge of smoke in accordance with the applicable rules and regulations.

If the corner fireplace will be placed near the inner wall, above which there is a certain drop in the roof structure, this moment must be taken into account - the fireplace's smoke pipe must be brought out above the ridge of the main roof.

In the process of prolonged use of the fireplace for heating, the smoke pipe, and in parallel with it the rear wall of the structure, will noticeably warm up. In view of this, the owners of buildings with wooden walls need to pay special attention to solving fire protection issues.

For the personal arrangement of a private fireplace, it is necessary, first of all, to establish its optimal dimensions for a particular heated room. In this manual will be considered the procedure for the construction of a heating unit for a small room with an area of about 15-20 m 2. If necessary, change the size of the unit in accordance with the characteristics of your particular situation.

After reviewing the proposed manual, you will learn the basic principles of the laying of corner fireplaces and in the future you will be able to build a similar structure without outside help.

The optimal size of the fireplace

In determining optimal sizes design, you need to take into account the performance of the area, as well as the volume of the room, which will be further heated by the erected unit. Specifically, in this example, a fireplace is built with a hole in the combustion chamber having an area of about 0.3 m 2. You can change the proposed size in accordance with the conditions of your situation.

Determine the optimal dimensions of the firebox portal. In the case of the construction in question, the portal is called a flue hole. Its main parameters are indicators of width and height.

Adhere to the standard ratio, according to which the width should refer to the height as 3: 2. In this example, the portal width will be equal to 560 mm, and the height will be - 400 mm.

The portal height of the fireplace and the depth of the fuel compartment should be kept as 2: 1, the ratio of 3: 2 is also acceptable.

These sizes are the most optimal. If the firebox has a greater depth, the heat output of the unit will decrease significantly. In the case of reducing the size of the firebox will appear smoke.

In this situation, the firebox must have a depth in the range of 240-300 mm.

After determining the optimal dimensions of the flue compartment of the corner fireplace, proceed to the calculation of the appropriate dimensions of the opening for the flue gas chimney. The dimensions of this hole should be selected taking into account the dimensions of the opening of the combustion chamber. The size of the hole for the chimney should be about 10-15 times smaller than the opening area of the flue compartment.

The optimal size of a rectangular chimney is 140x140 mm. If the cross section of the chimney is round, make a hole with a diameter of 100-120 mm. The optimal height of the chimney is 350-400 cm. This indicator may increase depending on the height of the roofing ridge.

In order to improve the heat transfer characteristics of the unit, back wall his firebox is laid out with a bias forward. This slope should begin to create about a third of the height of the firebox.

The design includes a smoke box. He settles down above the combustion chamber. Between the mentioned elements produced so-called. the eaves, also known as the pass. This element will prevent the release of soot, sparks, etc.

If your fireplace is laid out of carved bricks, make sure that all its dimensions correspond exactly to the standard masonry module. Typical dimensions of the building material in question are 25x12x6.5 cm. Keep the masonry seam at the level of about 5 mm.

In accordance with the cross section of the structure at the level of the flue compartment, other dimensions of the structure being erected will be determined. Perform their calculation and make a drawing-order, which will be masonry.

Also, the creation of the order and the execution of the necessary calculations can be entrusted to a professional. If desired, all necessary project documentation is easily found in open sources. Do as you like.

From what to lay out the fireplace?

After creating the order, calculate the required amount of building materials and purchase them in a specialized store. The material should be considered individually. And even incomplete products must be included in the calculation as whole elements. Additionally, add about 10% of the stock.

It is important that the brick is corpulent and properly burned. You can use a used brick from a disassembled furnace, if it is in a normal state. It is enough to clear the material from the remnants of the previous solution.

Spread the firebox of the corner fireplace from fireclay bricks.

To prepare the solution will need a number of materials. So, the sand for the solution should be quite coarse-grained (grains up to 1.5 mm). Pre-sand must be sifted and cleaned from all sorts of third-party inclusions.

Laying a fireplace will require the use of clay. The best option is Cambrian, it is blue clay. But if you are confident in the quality of local clay, you can prepare the solution with its use.

Also you need to buy materials for arranging the foundation. This is the usual Portland cement M400 and crushed stone with a diameter in the range of 20-60 mm.

Additionally, buy a smoke valve and steel bars. Bars with a length of 70 cm and a diameter of 10 mm or so are best suited. In this example, about 12 reinforcing rods are used. In accordance with the dimensions of your fireplace, their number may vary.

Preparatory work

Work on the arrangement of a corner fireplace begins with the construction of the base. It is strictly forbidden to connect the foundation of the erected structure with the foundation of the main building - this will lead to very adverse consequences.

To determine the optimal width of the foundation, add about 50 mm to the width of the front basement row. Define the length according to the dimensions of the side row of the base. In general, the dimensions of the base should slightly exceed the size of the future fireplace.

When choosing a place for arranging the foundation and the fireplace directly, make sure that the chimney does not pass through the elements of the truss system of the roof and the beam.

The foundation is done extremely simply - the foundation pit of the required dimensions is dug, the bottom of the pit is covered with waterproofing, a layer of a mixture of sand and gravel is poured over, the fittings are laid and the solution is poured.

Let the foundation gain strength and cover it with a double layer of roofing material.

While the foundation will harden, engage in the preparation of building materials for the upcoming use. So, the clay should be pre-soaked in water for a couple of days. Soak the bricks for the same time.

Pre-calibrate your existing bricks. Elements with significant deviations from the previously mentioned size cannot be used for laying.

To prepare the solution, use the standard and proven recipe. Pour the dry sifted sand with clay pulp, and then thoroughly mix the mixture. Determine the amount of water required individually. The finished mixture should have the consistency of jelly.

Check the finished solution. To do this, roll a sample of it in the form of a “sausage” about 1.5 cm in diameter. If the sample does not stick to your hands, normally keeps the shape given to it and does not disintegrate - everything is fine.

Also check how the solution prepared by you behaves directly on the brick. To do this, lay the mixture on the construction element. It is necessary that the solution does not stick to the trowel, does not disintegrate into parts and does not spread over the brick under its mass.

Masonry fireplace

Prepare the required drawings. The list of drawings necessarily includes ordering, section, and the facade of the fireplace.

During the construction process, you will use not only whole elements, but also halves of a brick and even three-quarters. Reflect this moment in the drawings with special conventions.

When laying the basement row, it is better to put the bricks on the edge - so the construction will look more interesting, but this requirement is not mandatory.

Starting from the 2nd row, lay the bricks flat. The bottom of the combustion chamber is usually settled at a height of about 250-300 mm above the floor surface, which is quite a comfortable indicator.

Proceed to laying. Your attention is invited to information about the order of laying. To make it clearer, at each stage refer to your existing drawings.

First step

Lay out 1-3 rows of bricks. Rows are solid, no special recommendations. The main thing is that the laying was as flat as possible. It is more convenient to start with the laying of corner elements.

Second step

Lay out the fourth row. It will be the hearth of a corner fireplace.

Third step

Lay out the fifth row. At this stage, you need to equip the ash-ash-blower. Support the grate from the three strips of steel. The strips will be fixed in the sixth row of the brickwork.

Soaked refractory brick lay on the clay mixture

Fourth step

Lay out the 6th row. At this stage of laying, lay the grate.

Fifth step

In the 7th row lay out the lower salary of the fireplace portal.

Sixth step

In 8-13 rows lay the walls of the fireplace portal. Bricks lay with bandaging masonry joints.

In parallel with this, start in the 11th row, and in the subsequent ones continue the construction of an inclined mirror near the rear wall of the fireplace.

Seventh Step

In the 14-15 rows, block the fireplace portal. Continue to lay out the mirror.

Eighth step

Complete the arrangement of the mirror in the 16th row. At the same stage, raise the upper part of the tooth. Be sure to coat the tooth with clay solution from the side of the smoke exhaust element. Such processing will protect the material from burning under the influence of high temperatures.

Step nine

Lay out the 17-19 rows of brickwork. At this stage you need to lay out the facade of the fireplace. Bricks must be cut in the direction of Heila.

Fireplace arch

Eleventh step

From the 23rd row to the end (in order) lay out the chimney.

In conclusion, the fireplace should be allowed to dry and then execute it. finishing finish and additional decoration at its discretion.

Overlap

Have a good job!

Video - DIY masonry fireplace

The number of country houses and cottages is only growing, therefore, stoves, which combine several functions at once, are beginning to be in great demand.

In addition, the corner option is quite compact and does not take up too much space in the room. Here it is important not to make a mistake with the desired model, and for this you need to take a closer look at the characteristics and prices.

Corner stove fireplace Cupid

It must be replaced every five years. The glass door of Japanese production perfectly withstands high temperatures and allows you to enjoy live fire.

In addition, heat flows through it. The convection system is also thought out.

- Small dimensions include a height that is a little over a meter, a width is about 80 centimeters, a depth is 63 meters.

- The combustion chamber has a good volume of 73 liters, which provides power up to 10 kW.

- The total weight of 157 kilograms allows for quick installation. For the chimney will require a pipe diameter of 150 millimeters.

That is why stove fireplace Cupid easily warms up the house within half an hour after a full load. Three kilograms of firewood is enough to make it comfortable and warm for eight hours.

Firewood can be replaced with brown coal briquettes, but stone cannot be used in any way.

Manufacturers guarantee at least ten years of work. At the same time, despite the imported components, the price of Amur is low and amounts to about 21 thousand rubles.

Comfortable model Yenisei with stove

It is not by chance that this stove was named this Siberian river. .

Yenisei is truly one of the most successful and powerful stoves. The corner option allows not only to warm up the house well over 110 square meters, but also to cook on two convenient burners.

The design of the firebox provides good review flame and fast warming up. All modern technologies and high-quality components are used here.

- For additional protection of the metal case heat resistant varnish is used.

- Fireproof chamotte performs the function of protection inside the combustion chamber.

- The glass is vitroceramic and can withstand up to 740 degrees.

- For good sealing of the door used heat-resistant cord.

Standard sizes include a height of 1140 mm, a width of 840 and a depth of 510 millimeters. Only power reaches over 11 kilowatts.

The presence of a cast iron plate is not strongly reflected in the weight of 176 kilograms. Chimney with a diameter of 150 millimeters can be connected to both the top and bottom of the system.

All installation is usually done independently. It remains only to put in the bottom of the wood or briquettes. Three to four kilograms will provide a full eight hours of heat. The price can vary from 24 to 25 thousand rubles.

Pechora is considered a good option for an angular stove. A power of 9 kilowatts allows for twenty minutes to heat the air in the room up to one hundred square meters.

- The height of a little more than a meter and a width of 760 mm make it possible to place it both at the wall and in the corner. Anyway, a panoramic view of the “live” fire will be visible almost from everywhere.

- The pig-iron grid-iron lattice allows to receive a powerful flame. Warming is obtained by convection.

- Heat-resistant glass not only withstands temperatures above 700 degrees, but also retains secondary gases. A pull-out ash drawer allows the ash to be removed without burning.

For the manufacture of the device used only imported components and high-quality structural steel.

Heat resistant paint covers the surface. To the furnace served as long as possible, it is best to lay it chamotte tiles.

Internal lining provides long heat. Full load is enough for 6-8 hours of work.

It will only be necessary to reload the firewood, which may be located at the bottom or briquettes.

For ten years of warranty work, you will have to pay from 22 to 23 thousand rubles.

A small model: a height of only 0.87 m and a width of 0.64 m makes it easy to install this small stove in the desired corner, especially since the depth is half a meter.

- The small power of 6 kilowatts allows you to warm up to 60 square meters of housing. The angular location makes it possible to maintain heat even in two or three adjacent rooms.

- Between the walls of the hull of high-strength steel and the furnace pass convection channels. Warm air enters through the upper part of the furnace, as well as the Japanese heat-resistant glass.

- To warm up you will need only three kilograms of small wood or briquettes. Only in no case can not apply the coal.

- The air in the room will warm up in half an hour and five or six hours of heat will be provided even in the mode of decay.

A fairly light weight of 95 kilograms allows for quick installation of the model. It will only be necessary to connect a chimney pipe with a diameter of 150 mm to the top of the system. Paul strengthen optional.

The warranty period is at least 12 months, and the price can vary from 16.5 to 17.5 thousand rubles.

Wall-mounted corner stove Bavaria with heat exchanger

Sophisticated design makes the stove-fireplace Bavaria very successful acquisition for heating a house of up to 90 square meters. The power of 9 kilowatts is enough.

Imported components of European quality and interesting design allow you to fit into any interior and decorate any room.

- A large German-made vertical glass-ceramic glass is inserted into the steel door.

- The water circuit, which is a heat exchanger, allows you to warm several rooms at once.

- This is facilitated by a convection system and a well-chosen grate.

- In order to serve the crowd as long as possible, it is covered with chamotte tiles from the inside.

- The "clean glass" system provides full afterburning of exhaust gases. It does not require a large consumption of wood or briquettes.

Overall dimensions are small: height is about 0.9 m, width is 0.6, and depth is about 0.5 m. Weight reaches 140 kilograms.

The side panels are very decorated with ceramic inserts. Mostly they are made of marble. The chimney can be connected to both the top and the back of the system.

Bavaria has various modifications, so its price can vary from 20 to 30 thousand rubles.

Rhine - for stylish and fast heating

Ray n No wonder it is considered one of the most stylish stoves, fireplaces. Successfully created design is embodied in a small design.

Despite the height of 1155 mm, a depth of 485 mm and a width of 0.6 m, as well as a small weight of 120 kilograms, such a fireplace allows you to transform and heat any room.

- A power of 10 kilowatts will not freeze in a house of over one hundred meters.

- Rapid air heating already within the first five minutes is possible due to a successful convection system.

- Good grates give a flame to flare up quickly, and heat-resistant glass allows not only to get warm, but also to admire the fire.

- Already three kilograms of briquettes or firewood make it possible to retain heat for 6-8 hours.

This can also be done because there are convection channels between the case made by stainless steel mz and the firebox lined with chamotte tiles.

Therefore, the efficiency reaches over 75 percent, which fully justifies the price at about 27-28,000 rubles.

Wood stoves fireplaces, which are produced by Meta, are distinguished not only by a wide range of various models, but also by high quality.

- In addition to the use of high-strength steel, only components made according to all European standards and mainly imported are used.

- Japanese glass-ceramic glass withstand more than 700 degrees and provide protection against carbon monoxide. In addition, they allow you to get a panoramic view of 360 degrees and enjoy the view of burning logs.

- Wall or corner option is perfect even for a small room. It does not require additional surface cladding.

- Perfectly designed convection system, which allows you to warm up to one hundred and over square meters of housing in minutes. Heat persists for a long time from six to eight hours, even in smoldering mode.

- Small sizes are combined with a thoughtful design. At the same time there is a very high rate of efficiency. It reaches over seventy percent.

A simple installation system will only require the connection of the chimney. Low weight, which ranges from one hundred kilograms, does not require additional reinforcement of the sexes.

The average lifetime is at least ten years, but the prices are quite reasonable. Depending on the model, they usually range from 16 to 30 000 rubles.

About the device of the angular furnace is shown on the following video: