What is thermal grease? The best thermal pad for a laptop.

Why do we need such devices? The fact is that the surface of the processor or radiator can not be completely smooth. If you place the radiator directly on the processor, there will be tiny, almost imperceptible gaps between them. And since the air conducts heat poorly, these gaps will have an extremely negative effect on the cooling of the entire system.

What is better to use: thermal paste or thermal pad?

For this reason, an intermediate material with high thermal conductivity is required, which can fill these gaps and establish heat exchange. Thermal pad or thermal paste can be used as such material. But which one to choose? What is the difference between them, what are the advantages and disadvantages? Which option is best for a laptop? Understand this will help you our article.

Thermal grease or thermally conductive paste is a sticky substance that is applied directly to the radiator or the processor itself to ensure a snug fit. Thermal grease is the most commonly used material that provides correct cooling for electronics. To perform its task, the thermal grease must be of good quality. To properly apply this substance requires a certain skill, as it is very dirty.

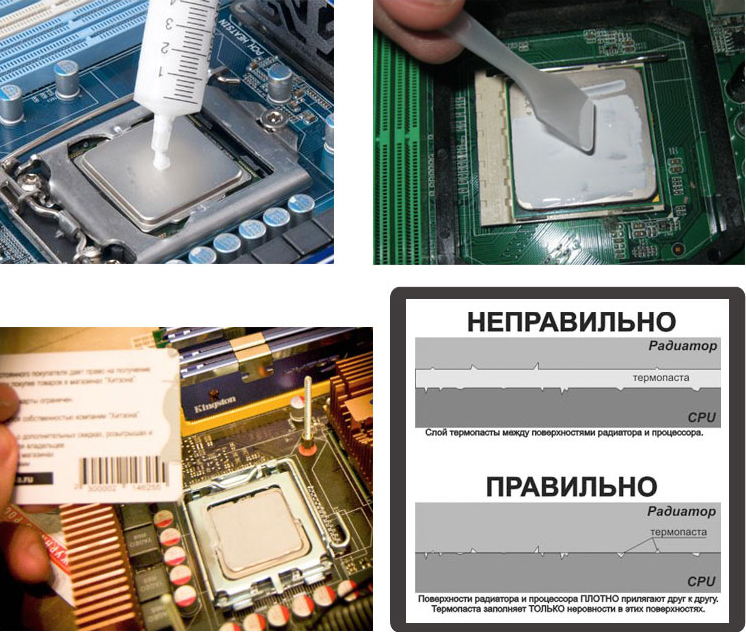

For proper application, it is common to extrude a pea-sized amount of paste directly onto the central area of the processor. Then it is evenly distributed over the entire surface using a flat object: for example, a plastic card. The layer must be thin enough to fill possible gaps, but it does not create an additional barrier between the processor and the heatsink.

What is a thermal pad

The main advantage of this element is ease of installation. Unfortunately, in terms of their effectiveness, thermal pads are inferior to thermal grease, which can be applied with a thin layer and obtain the desired result. Some fans for processors are sold immediately with thermal pads, because they are easy to install, do not require additional manipulation and do not need to get dirty, while they provide the necessary performance. But, unfortunately, these items are disposable.

If you ever need to remove a radiator from the place where it was once installed, the thermal padding will have to be replaced. This is due to the fact that the surface of the thermal pads is disturbed during contact with the processor and becomes uneven. Thus, if you try to install it again, gaps form between the two surfaces. As already mentioned, this adversely affects the thermal conductivity and can disrupt the operation of the processor. Therefore, it is worth remembering: if you remove the radiator, the thermal pad should be completely removed and replaced with a new one.

Also, do not use multiple thermal pads together. Two or more gaskets between the processor and the radiator instead of cooling will have the opposite effect and very quickly lead to damage to the processor. This is especially true for fast-heating notebook processors.

Replacing thermal pads with thermal grease

Technically, replacement is possible, but it is not always recommended. In most cases, such a replacement will cause the CPU temperature to rise. Why is this happening? The fact is that the thermal pad not only provides thermal conductivity, but also has a certain effect on the springs and bolts that hold the entire cooling structure of the processor.

If the gasket is removed and the paste is applied instead, the radiator will not rest on the processor as tightly as before, since an element of a certain thickness has been removed from the established system. In addition, the rotation of the fan can have a certain effect on the processor due to the resulting gap, causing friction. Therefore, it is possible to replace one element with another at your own peril and risk.

TIP. Recently, however, the production of special types of thermal paste has begun, which is used instead of thermal pads. It is more dense and viscous, can fill large gaps, in addition, it has improved thermal conductivity. Pay attention to the thermopaste brand K5-PRO, it is made for iMac computers, but also suitable for other computers.

Thermal grease and thermal padding: applying one to another

Such an action does not make sense and can only degrade thermal conductivity. Applying the paste to the gasket under certain conditions can seriously hinder the transfer of heat from the processor. Therefore, it is better not to experiment, and instead choose only one option.

Laptop option

It should start with the fact that both gaskets and pasta are of poor and good quality. Undoubtedly, good quality thermal grease will be better than bad thermal pads, and vice versa.

But if we consider the situation with elements of the same quality, then a thermal pad is recommended for a laptop. The fact is that the heating of the laptop processor is strong enough, moreover, this device is constantly subjected to shaking when moving from place to place. A good thermal pad will be more stable in these conditions, and it is better to choose it instead of thermal paste.

Thermal grease and thermal pads: advantages and disadvantages

Let's start with thermal pads. So what advantages do they have?

- Easy to use.

- They can be cut in different sizes and shapes.

- Do not get dirty, easy to install.

- Do not dry out.

- Made of various materials in accordance with the specification.

Disadvantages:

- High production cost.

- Single use.

So, at first glance, thermal pads have many advantages. Different in shape, you can quickly install a new one instead of the old one, easy to install. The various types of materials from which they are made, allow you to choose the most preferred material in terms of electrical, thermal, chemical or physical use.

However, their price can be quite high. Most often, in the production of components, thermal pads are set manually, which immediately increases the cost of the final product.

Now consider the characteristics of thermal paste. Benefits:

- Reliability.

- Cheapness

- High-quality elimination of gaps.

- Only a thin layer is required.

Disadvantages:

- Soiled when applied.

- Dries up.

- Sufficient pressure is required.

Let's sum up. Thermal pads are a good option, especially for a laptop, but you need to take a responsible approach to their choice. It is better to take a good thermal grease instead of cheap substandard thermal pads. Also, when choosing the latter, you can focus on the type and quality of the material. This gives you more control over your system.

TIP. If the price is essential to you, it is better to make a choice in favor of thermal paste. You will need to apply only a thin layer in order to achieve good thermal conductivity. Moreover, the thinner this layer is, the better the thermal conductivity will be. Thermal pads are almost always much thicker than the required layer of thermal paste.

Also, thermal grease copes much better with the alignment of surfaces. Since it is a viscous substance, this substance is capable of filling both the smallest gaps and rather large irregularities. It copes with this task much better than thermal pads, which do not have the ability to "flow" into all the grooves. If the surface of your components or radiator has significant irregularities, it is better to give preference to thermal grease.

When you make a choice, it is advisable to install a component temperature control program and monitor indicators for a while to make sure that your choice was correct.

Many users faced the problem of overheating in their computers, and if stationary machines can be equipped with additional cooling, then laptops are deprived of this advantage. After a year or one and a half after the purchase, they begin to overheat, the cooling pad does not help either. What is the matter? It's simple: it's time to change the thermal interface.

Purpose

Any thermal interface is designed to transfer heat between two objects, it should have low thermal resistance and high thermal conductivity, as well as zero electrical conductivity, low fluidity and the ability to maintain its properties at temperatures close to 100 degrees Celsius. What is better - thermal paste or thermal padding? The thing is that they have a different purpose.

Common species

For a long time, the only thermal interface was thermal paste, familiar to everyone, perhaps. This viscous composition in the form of a cream (paste), which does not conduct electricity, has been used and is used for all computer parts that need cooling: video cards, chipsets and radiators. Over time, there were other thermal interfaces: thermal pads, hot melt glue, and even liquid metal, so there is a lot of confusion. Each type of thermal interface has its own characteristics, so even the common question of what is better - thermal grease or thermal padding can be solved by the user himself, because they simply have a different purpose.

Thermal padding

On the Internet, there are other names of this type of thermal interface: thermal sleeve, chewing gum, thermal cut. Their main task is to fill the space in excess of 0.5 mm. Copper plates have appeared on the modern market that supposedly can replace thermal pads, but this is not the case: copper is inelastic and cannot guarantee uniform adherence over the entire surface. In addition, the surface of the chip and the radiator sole, although polished, still have some irregularities, and in addition to simply filling the gap between the parts, it is necessary to smooth out roughness and minor irregularities: this function is performed by paste or thermal padding.

What to choose as an alternative? In the event that it is nevertheless decided to use a copper plate, it should be well polished and adjusted, so when buying it is better to take a sheet a little thicker than necessary. The use of a thin layer of thermal paste on both sides is also necessary for filling microcracks.

Features of thermal sleeves

Sometimes it is possible to find the statement that a thermal sleeve is used for gluing, fastening two parts, if there are no other ways. This is a delusion, because in such cases hot melt glue is used. Termozhvachki, as a rule, are used for CPU power supply, as well as for memory chips on video cards and motherboards.

It is also possible to “land” on it, since the temperature of this part increases evenly, without jumps, and in general is not as high as on the processor, so the question of whether thermal paste or thermal padding is better is incorrect here: paste will not be able to perform the same functions.

Hot melt glue

This term is called a special compound that does not conduct electrical current. It has a high thermal conductivity and serves to attach small radiators to the video card, processor power subsystems, and so on. Hot-melt glue does not dry out for a long time, but it can not always provide high-quality fastening, and its thermal conductivity, in comparison with other types of thermal interface, is much lower, which is quite logical if we consider that this product has a different purpose. It is recommended to use it only if it is impossible to attach the sole of the radiator to the processor with anything else.

Liquid metal

Another type of thermal interface, which, by the way, has an excellent electrical conductivity, because it consists mainly of metal. Nevertheless, it is very popular among enthusiasts, because the liquid metal has thermal conductivity and thermal resistance values much higher than any other thermal interface. Before applying the thermal distribution cover of the processor and the heatsink base should be degreased, after which you can rub liquid metal. The layer must be very thin. It is necessary to rub in until the composition ceases to be fluid.

This interface is the most effective, but it is extremely inconvenient to apply and remove. Before use, you must ensure that the base of the cooler is copper or nickel-plated, since the liquid metal reacts with aluminum alloys.

Thermal Interface Replacement

When buying a thermal paste, you should first pay attention to its consistency: it should not be too liquid or too thick, because in the first case there will not be the necessary contact, and in the second - you will not be able to apply the composition in an even thin layer. Computer masters most often use thermal paste MX-4 or KPT-8.

However, the first step is to remove the old composition. If the last shift was made more than a year ago, it is necessary to carefully separate the radiator, because if the paste or thermal pad is dried, with careless handling, you can simply "pull out the root" all the details.

In laptops

Special care should be taken when replacing the thermal interface in laptops, starting from the disassembly stage. The fact is that the processor chip is not protected by metal there and is very sensitive to damage. If the previous thermal grease had an admixture of aluminum chips, it is necessary to avoid contact with other parts, because it can cause a short circuit.

In no case can you use silicone thermal grease, as it has a very low rate of heat dissipation and, moreover, dries very quickly. Such a paste needs to be changed more often, otherwise the device may break due to constant overheating.

What is better - thermal grease or Usually in compact computers, all the details fit tightly together, so there is no need to use thermal pads, but before you make a choice, you need to check the gaps.

Proper application

When applying thermal paste, it must be remembered that the composition should lie down in a thin even layer, without gaps and bubbles. The amount of paste, on the advice of computer masters, should be a little more than a match head. Here is no longer better. The thermal interface should be distributed over the surface with a special spatula, and it is only necessary to apply it on the heat distribution cover of the processor.

Good thermopaste is changed once every two to three years, poor - once a year, but it still needs to be changed, even if the expected service life has not yet come to an end. In stationary computers, you do not need to remove the radiator during cleaning, so the thermal interface does not suffer, but the masters still say (regardless of whether there is a thermal pad or thermal paste) that it is better to replace at the same time.

Thermal change

What is better - thermal paste or thermal padding? For a video card, the answer is unequivocal: option two. In order to substantiate the answer, it is not necessary to contact the computer master, you just need to know the gap between the two parts. In the case of a radiator for a video card, this is usually just over 0.5 mm.

To install a thermal pad, you need to cut the desired piece, the size corresponding to the chip or slightly larger than it. Then remove the film from the surface of the thermal pads. Fold a piece into a roll-like or bend and start laying at one of the edges to prevent air from entering (resembling the process of gluing the protective film to the screen of a phone or tablet). After this, it is necessary to separate the second, ribbed film from the thermal pad. The process is completed, you can install a radiator.

Without knowing the parameters

Many manufacturers say that the best pasta or thermal pads of the same companies that they used, however, such a moment as the gap between the heat distribution cover and the radiator cannot be found in the description of the technical characteristics of the computer, so there is an instruction how to replace the thermal interface without knowing the thickness.

First, according to the above instructions, you need to install a gasket 0.5 mm thick and attach a radiator, then unscrew and remove it again to check if the thermal pad is pressed. If there is a deformation area, then everything is in order, and you can simply put the radiator back.

If the pressure does not occur, you need to cut another piece of thermal pad of the same size and install it in the same way over the first one, then reattach the radiator and remove it to check the degree of pressure. Repeat this process until the deformation region appears.

If the instruction is followed, then the total thermal conductivity of two or more thermal pads will be no worse than one.

Do it yourself

For a long time in a free access in almost every computer store there is a wide variety of goods. There can be purchased or hot melt, or thermal pad, or thermal grease. What is better - to buy or do manually? The fact is that homemade thermal pads can be made from ordinary thermal paste and medical bandage.

The cost of "chewing gum" is relatively low, given the long service life, but sometimes it happens that there is no opportunity to purchase it. To make it autonomously, you need a medical bandage (the finer the mesh, the better) and thermal paste (preferably two, viscous and liquid). The second option: a plate of copper or aluminum and polishing material for them.

First you need to cut a suitable piece of bandage with a margin of 3-5 mm. Smear the sliced pieces with thermal grease. This should be done carefully so as not to damage the bandage fibers. Such a "grid" gives the thermal paste rigidity, and it will not spread even with strong heating, although heat transfer suffers a little from the use of the bandage. Before applying new gaskets on the parts, you should smear them with a thin layer of thermal paste to facilitate installation. Then cut off all the excess with scissors and tamp with a thin screwdriver.

Instead of bandages, you can use copper or aluminum. To do this, using metal shears, cut plates of metal, polish them well and install in the same way, after removing the remnants of old gaskets and smearing the surface of the chips with a thin layer of thermal paste. User tests show that it gives a gain of three degrees compared with aluminum, and five degrees compared with bandages. Factory thermal pads lose properly installed plate of copper by ten degrees, but remember that, as a rule, these products are not the best.

Final choice

Many manufacturers are now sinning because instead of thermal paste they use thermal seal on all parts that need a thermal interface. Yes, laying is much simpler in an installation, so they can be understood: production optimization and the like. What is better - thermal paste or thermal padding? For the processor, the latter is not the best option, especially if we talk about laptops, because the thermal conductivity of the “chewing gum” is lower than that of the paste, and the distance between the processor and the radiator sole is very small. Since the thermal gasket usually has a thickness of about 0.5 mm, with such a strong compression it will deform and lose most of its properties. The maximum allowable compression ratio is 70%.

Having clarified the purpose of each type of thermal interface, you can easily understand whether paste or thermal padding is needed. What is better to choose depends only on the functionality.

July 13, 2017

Overheating of internal parts is dangerous for any equipment. This is especially true for PCs and laptops, in which processors and video cards are often covered with special thermal grease. Often install and thermal pads. They fill the space between the cooler radiator and the chip, which also helps to improve heat transfer. At the same time, many users have a question: "And what is better - thermal paste or thermal padding?". Let's try to figure it out.

First, let's talk about thermal paste. It is a multicomponent dense (sticky and plastic) substance with high thermal conductivity. It consists of various synthetic or mineral oils, metal powders, oxides, etc. Thermal grease is the most common material used to properly cool electronics.

As for the functions of thermal paste, they are as follows:

- Filling the void between the processor / video card and the cooler radiator (due to which an important part may overheat);

- Providing heat transfer from the processor to the cooling system.

The disadvantage of thermal paste is that during operation it dries out and loses its properties. Therefore, it is advisable to carry out its replacement for prevention at least once in 6-12 months. Unfortunately, many users ignore this. As a result, their PC or laptop fails due to overheating.

However, despite all this, computer manufacturers continue to actively use thermal grease to protect processors and video cards from overheating. Although now there are many other thermal interfaces. For example, the most popular alternative to thermal grease is thermal padding.

What is a thermal pad?

![]()

On the Internet you can find a variety of names for this thermal interface - thermal cable, “chewing gum”, hot melt glue, thermal rubber, etc. Thermal pad is also used to cool important PC parts that are characterized by high temperature conditions. What does she represent? In fact, it is a thin elastic sheet consisting of a base and a filler (graphite or ceramics).

In this modern market offers several types of thermal pads. They differ from each other as follows:

- Thermal conductivity;

- Thickness (as a rule, it varies from 0.5 mm to 5 mm);

- "Construction" (we are talking about the fact that the thermal pad can be single-layer or two-layer, and also have one or two adhesive surfaces);

- The material (rubber, silicone, copper, ceramics, aluminum; there are homemade options - for example, from a bandage impregnated with thermal paste).

So if you decide to put a thermal pad or just change the old one to a new one, then be sure to consider its thickness, thermal conductivity coefficient, and other characteristics.

Also pay attention to the production date. If the thermal pad was released more than a year ago, then you should not use it.

What to choose?

Let's try to answer the question, what is better for a laptop or PC? Thermal grease or thermal padding? We will sort by points:

- Let's start with the fact that thermal padding is inferior to paste in its effectiveness, if the distance between the part and the cooling system is minimal. For example, literally 0.2-0.3 mm. If the distance is close to 1 mm, then thermal paste cannot be used. Overheating otherwise ensured.

- The thermal padding shows itself well if it is used in devices where the seats of the chip and the cooling radiator are distant from each other (more than 0.5 mm). After all, if you take a thermal paste here, then there will be no sense from it. Due to the thick layer, a very low heat sink index will appear. The processor or video card will start to get very hot.

- Replacing thermal pads is often simpler than applying a new thermal paste, which requires cleaning from the old paste, and a thin uniform layer, and even special tools. However, it is not always easy to replace the thermal pad on the processor or video card. It is necessary to choose the right size for it, take into account the thickness, the degree of compression (should not be more than 70%, otherwise, due to severe deformation, it will lose most of its heat-conducting properties) and many more. other

- Price. This criterion will not allow us to identify which is better. Since the cost of thermal paste and thermal pads is about the same. The cheapest options for such thermal interfaces will cost you 100-150 rubles. However, we do not recommend saving. It is advisable to choose products whose cost exceeds 300 rubles.

- Life time. Much depends on the quality of thermal paste or thermal pads. Although on average the latter serves a little more. However, if for some reason you need to remove the cooler radiator from a video card or chip, then you will have to change thermal grease and thermal padding.

- On average, thermal conductivities in thermal conductivity are inferior to thermal grease, the best samples of which have indicators at the level of 8-10 W / mK. Thermal pads have no such values. They have a coefficient of thermal conductivity below. On the other hand, there are thermal paste with a thermal conductivity of 1-2 W / mK. In most cases, they will already yield to thermal pads.

It turns out that each option has its pros and cons. Therefore, it is impossible to say for sure what is better and what is worse. Experts recommend the following:

- For laptops and netbooks use a thermal pad. They argue that the processor and video chip in such devices heat up more. In addition, a laptop or netbook basically does not stand in one place. He is taken with him to work, study or visit, and, therefore, he is often subjected to shaking. In such conditions, a good and high-quality thermal padding will be more practical and reliable. Therefore, it is better to choose it instead of thermal paste.

- PC owners prefer thermal grease. Indeed, on most models, the gap between the processor and the cooler radiator is minimal. It is difficult to place even a thin aluminum or copper plate.

Remember! If you change the thermal interface yourself (for the same laptop), then the thickness of the new thermal pad should be a little more (about half a centimeter) than the previous one. The fact is that during operation it is slightly compressed. In addition, if you are not sure how thick the thermal padding is for your PC or laptop model, then take 1 mm. This is the most common and standard gap between the radiator and the chip in many devices from various manufacturers.

Is it possible to replace thermal grease with thermal padding (and vice versa)?

Theoretically, the replacement of thermal paste on the thermal pad is possible. However, in practice it is not always recommended. The reason is that in most cases, the replacement of thermal paste on the thermal pad and vice versa leads to an increase in the temperature of the processor or video card. Why? Let's take a look at a few examples:

- If you remove the thermal pad and apply the paste instead, the cooler radiator will most likely not fit snugly to the processor or graphics adapter. The fact is that most thermal pads are much thicker than the allowable layer of thermal paste. In this free space will begin to get air that conducts heat poorly, contributing to the overheating of the device.

- If, on the contrary, instead of thermal paste to install a thermal gasket, the pressure on the springs and bolts holding the entire structure of the cooling system will increase. From which it can fail at all or work unstable.

Therefore, it is not recommended to change the thermal grease to the thermal pad or vice versa. Use the same thermal interface that was previously used. That is, if the manufacturer has applied thermal paste between the processor and the cooler, do the same, giving preference to this thermally conductive substance. Risk is not worth it.

Also, do not forget that it is forbidden to apply thermal grease on a thermal pad or vice versa. Such a “neighborhood” will only have a negative impact and degrade thermal conductivity. What does it threaten with? The failure of the video card, the failure of the motherboard or processor.

- We already wrote above that if you are not sure which gasket to take on your model of processor or video card, then give preference to the product with a thickness of 1 mm. This is the standard gap between the chip and the cooler radiator on most devices.

- It is also not scary if the thermal padding is thicker. For example, 2 mm instead of 0.5 mm. But only under the condition that as an attachment bolts, which are sufficiently strongly pressed radiator. The result will be the same 0.5 mm at the junction. So if we are talking about the replacement of thermal pads, it is better to take thicker than thinner.

- In no case should not save as when choosing a thermal paste, and gaskets. Too much depends on this material. In addition, due to the use of low-quality thermal interfaces, you can "get" to repair or replace expensive components.

- Despite the good thermal conductivity of copper gaskets, they must be used carefully. The fact is that copper does not differ in plasticity and flexibility. Therefore, if the surface of the radiator is uneven, then a gap may appear between it and the processor or video card into which air enters. All this will lead to excessive heating of the part.