Technical design of the hydraulic cylinder arrow.

Aesthetic cosmetology

G. Goltsblat, chief designer of ZAT "BAKM" The oldest crane manufacturing plant in the region is Balashikhinsky ( joint stock partnership

"BAKM") is experiencing a friend's youth.

Since 1993, despite the difficult economic situation, the enterprise has completely updated the products that are being produced, and has mastered the production of new highly efficient machines - manipulator cranes, which are increasing x release, creates new models, expands the number of their sizes and modifications.

Manipulator cranes and crane-manipulator units (CMU), which are manufactured by JSC "BAKM", are used on commercial vehicles, tractors, ships, skid platforms, special transport devices and stationary. Unfortunately, compared with such well-known types of machines as self-propelled jib cranes and manipulators, manipulator cranes are still little known to the general public. Their virtues are being conquered by far from the new world.

|

At Zakhod, these cars are produced at least sixty years ago.

Cranes-manipulators of JSC "BAKM" are primarily used for the mechanization of crushing and cutting robots: suitable for the movement of vanes, both single and in containers, bags and on pallets, as well as loose, lump, wood varieties items from other long-dead worlds, scraps and all sorts of things .

others

|

The stench is effectively detected in low-surface everyday life, with repair and renovation robots, on pink-colored objects, in constricted minds, and with success in replacing jib self-propelled cranes.

Manipulator cranes in the “grab” type are thus equipped with hydraulic lines for driving active working parts (grabs, pliers, rotators, hydraulic drills, etc.) with couplings connecting the hydraulic couplings.

Leading foreign companies produce manipulator cranes with a lifting torque of 1 to 80 t m, a maximum lifting capacity of up to 20 t and a height of up to 30 m. Of these, the most popular are those that are being developed in angling moment 8 – 10 t m. Additional investigation carried out by TsNDIOMTP (Moscow), showed that in the minds of Russia the greatest demand is also for the 8 - 10 t class. At this stand, JSC "BAKM" developed the concept of developing a unified series of manipulator cranes with lifting torques ranging from 4 to 25 t m. Based on the establishment of priorities by the first mass crane the pulator from this series became MKS-4032 (BAKM 890) with a vantage moment 8.9 t m, serial production of this kind began in 1993. The MKS-4032 manipulator cranes were almost entirely produced by Balashikha and other factories that were produced earlier.

|

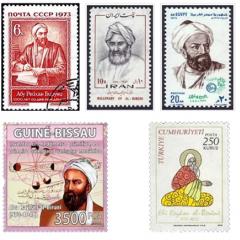

Kolyshny SRSR

Our largest truck cranes have a lifting capacity of up to 6.3 tons and often 10 tons of truck cranes.

The leather crane manipulator is equipped with an automatic anti-vantage protection system. The MKS-4032 family fully complies with the Rules for the design and safe operation of vanity taps. international standards

|

, and in 1997, the first industrial cranes were certified under the GOST R system.

Due to its technical capabilities and characteristics, the ISS-4032 does not compromise with the best foreign satellites.

At the same time, JSC “BAKM” is constantly working on further development and expansion of capacity, and also creates new models of cranes in a range of standard sizes.

The impact of manipulating cranes with a pull-out torque of 4.6 has already been completed;

12 and 16 t m. Through manipulating cranes with a pull-out torque of 20 and 25 t m.

|

In the past, the BAKM 460 crane with a lifting torque of 4.6 t m has been tested. The first industrial batch for light-duty vehicles ZIL-5301 “Bichok” was produced in the first quarter.

These machines are especially widely used in various spheres of the Lord's rule.

Behind the washers, these machines may be equipped with an electro-hydraulic proportional control system, which allows the operator to operate both on stationary consoles, located on the sides of the support frame, and remotely using a portable a remote control with richly functional handles for controlling work operations (joysticks).

|

It is also possible to install a pre-chewing alarm at 90% pressure and a drive at pressure level that exceeds 100%.

At this time, the company's facilitators are working on the construction of crane-manipulators of special design for important operating modes, which are used in intensive excavation-removal robots with decks (or synavantage manipulators) and metalbrucht.

The operation of such machines is associated with the vibration of decks (whips) or the removal of metal from rubble and pulling on the ground.

|

It is characterized by high fluidity of work operations, significant dynamic pressures, which include the possibility of stagnation of the equipment, and the need to protect structural elements from damage during operation and re-driving in off-road areas.

Additional capabilities of manipulator cranes for external purposes are achieved when they are equipped with a cradle.

All this could not but appear on the cost of the products, as, prote, is significantly lower than the price of leading analogues, which makes it possible to replace imported high-quality and cheap technology and ham.

Automobiles-self-vantographers with on-board cranes-manipulators are used for the delivery of containers and packaged household goods, goods on pallets, as well as for the mechanization of transport-warehouse, repair-refurbishment and construction-assembly robots of small scale on rose-colored areas Ektakh.

On-board cranes perform self-referencing and self-revealing of the base vehicle and, therefore, repositioning and re-launching of other standard transport means.

The main parameter of manipulator cranes is the maximum pull-in torque.

The cranes are equipped with hydro-coated telescopic booms with one, two or more flexible sections with the possibility of installing mechanical cushions.

Cranes-manipulators can be used as a tool for the working organ.

The clamshell conveys the hardening of active drive hydro-coated replaceable working parts - a grab, a hydraulic drill, a clamp, etc.

The placement of manipulator cranes on motor vehicles can be: on the chassis of the trailer vehicle between the cabin and the trailer platform - at the middle and rear part of the trailer platform;

on a truck tractor between the cab and the fifth wheel unit;

on the chassis of the vehicle - at the rear, middle and front parts of the vane platform.

The rotator ensures manipulation of the rotor in a horizontal plane through a rack transmission and a double-acting hydraulic cylinder 21, the rod of which is the rack 22 of the rotor, which fits into gear 23. The rotator is stored for containers.

Rotation of the boom arm in plan up to 420° is ensured by a rack-and-pinion rotating mechanism, which includes two alternating hydraulic cylinders, rack 7 and gear 8 rigidly fixed to shaft 9 of the rotary column. The drive of the axial piston pump 3 of the hydraulic system of the manipulator is driven by the vehicle engine 1 through the pressure selection box 2. The manipulator can be controlled from either of two control panels 4 , damaged on the sides of the car. Designs of industrial onboard manipulators of Vikonian as a unit

principle diagrams

and differ among themselves on the importance, the importance, the number of boom sections, the height of the lowering hook, the weight, the overall dimensions.

The main manufacturers of on-board cranes-manipulators SND are: JSC "BAKM" (metro station Balashikha, Moscow region), VAT "Stavropol Automobile Crane Plant "KRAST"".

Manipulator cranes are also produced by AT Inman (Bashkortostan). |

JSC "BAKM" produces manipulator cranes of the BAKM series with a pull-out torque of 46... 160 kN - m. In the future, the production of loader cranes with a pull-out torque of 200 and 250 kN m has been transferred. Technical characteristics of the loader cranes The BAKM series is listed in the table. |

14. |

|

Table 1. Technical characteristics of crane-manipulators BAKM 460 |

||

|

Parameters |

||

|

BAKM 460-1 |

||

|

BAKM 460-2 |

||

|

on the same suspension |

||

|

on the bracket at the base of the line |

||

|

Maximum line height, m: |

||

|

Main |

||

|

with a mechanical rubber band |

||

|

Maximum lift height, m |

||

|

Frequency of colony wrapping, xv |

||

Cut to the turn of the colony, hail

Manipulator cranes are also produced by AT Inman (Bashkortostan). |

Pump flow, l/hv |

|

Vlasna mass KMU, kg |

Basic car |

|

|

Table 2. Technical characteristics of crane-manipulators BAKM 890 (MKS-4032) |

||

|

Strila |

86 (63)* |

|

|

Table 1. Technical characteristics of crane-manipulators BAKM 460 |

2,4 (1,65)* |

2,27 (1,65)* |

|

Parameters |

4(3)* |

4 (3)* |

|

BAKM 460-1 |

||

|

BAKM 460-2 |

||

|

two-section |

||

|

trisection |

||

|

Number of hydraulic telescope sections of the line |

||

|

Maximum pulling moment, kN m |

||

|

with mechanical cushions |

3 (4,5)* |

3 (4,5)* |

|

Main |

||

|

Lifting height, m: |

||

|

with a mechanical rubber band |

||

|

main line |

||

|

boom with mechanical guards |

||

|

Colony wrapping frequency, min-1 |

||

|

Maximum operating pressure of the hydraulic system, MPa |

||

|

Overall dimensions in transport position, mm: |

Vlasna mass CMU with wine supports, kg: |

|

with base 3.5 m

with base 4.6 m

Manipulator cranes are also produced by AT Inman (Bashkortostan). |

Basic cars |

|||

ZIL, KAMAZ, Ural, MAZ |

* Vikonannya for the important robot mode. |

Table 3. Technical characteristics of crane-manipulators BAKM 1200* |

Vikonannya |

|

|

Number of hydraulically telescoping sections of the line |

||||

|

Strila |

||||

|

Maximum vantage point, t |

||||

|

BAKM 460-1 |

||||

|

BAKM 460-2 |

||||

|

two-section |

||||

|

Rising height, m |

||||

|

Main |

||||

|

Working vice for hydraulic system, MPa |

||||

|

with a mechanical rubber band |

||||

|

Vit, m/vantage, t |

2,4/4,8; 4,3/2,8; 5,9/2 |

2,4/4,6; 4,4/2,6; 6/1,85; 7,6/1,25 |

2,4/4,4; 4,5/2,45; 6,1/1,75; 7,7/1,3; 9,3/1,05 |

2,4/4,2; 4,6/2,3; 6,2/1,65; 7,8/1,25; 9,4/0,98; 11/0,8 |

|

Mass of CMU, kg |

||||

|

Overall dimensions in transport position, mm: |

KamAZ, Ural, KrAZ, MAZ, ZIL |

|||

* This model was taken from the production industry and is widely used in the industry.

Table 4. Technical characteristics of crane-manipulators BAKM 1600

Manipulator cranes are also produced by AT Inman (Bashkortostan). |

Basic cars |

|||

BAKM 1600-1 |

BAKM 1600-2 |

BAKM 1600-3 |

BAKM 1600-4 |

|

|

Number of hydraulically telescoping sections of the line |

||||

|

Strila |

||||

|

Maximum vantage point, t |

||||

|

BAKM 460-1 |

||||

|

BAKM 460-2 |

||||

|

two-section |

||||

|

Rising height, m |

||||

|

Main |

||||

|

Working vice for hydraulic system MPa |

||||

|

with a mechanical rubber band |

||||

|

Vit, m/vantage, t |

2,4/6; 4,3/3,7; 5,9/2,7 |

2,4/5,9; 4,4/3,5; 6/2,55; 7,6/1,8 |

2,4/5,7; 4,5/3,35; 6,1/2,4; 7,7/1,85,9,3/1,5 |

2,4/5,5; 4,5/3,1; 6,2/2,25; 7,8/1,7; 9,4/1,35; 11/1,1 |

|

Overall dimensions of the CMU in transport position, mm: |

||||

|

Mass of CMU, kg |

||||

|

Overall dimensions in transport position, mm: |

KamAZ, Ural, KraZ, MAZ |

|||

VAT "KRAST" produces cranes-manipulators of the MKS series with a pulling torque of 10...174.4 kN.

Below is the technical characteristics of the crane-manipulator MKS-10313:

|

Strila |

|

|

Vantage capacity, kg: |

|

|

on villoti 1.1 m |

|

|

on villiot 2.2 m |

|

|

on villiot 3.25 m |

|

|

Maximum height, m |

|

|

Hook lift height, m |

|

|

Line type |

Telescopic |

|

Number of sections of the line |

|

|

Turn around, hail |

|

|

Working vice, MPa |

|

|

Basic chassis ZIL-5301BO |

Technical characteristics of the crane-manipulator MKS 5531A:

|

Pull moment, kN m |

|

|

The greatest flight (with the main jib, jib and jib jib), m |

|

|

Shot length, m |

|

|

Turn around, hail |

|

|

When the shooting hits, hail |

|

|

Maximum height of the lift (with the main boom, jib jib), m |

|

|

Maximum depth of lowering, m |

|

|

Nominal working pressure, MPa |

|

|

Maximum pull-up-lowering fluidity, m/s |

|

|

Overall dimensions for transport position |

|

|

(length x width x height), mm |

2500 x 880 x 2300 |

|

mass, kg |

|

|

Installation options |

|

|

Overall dimensions in transport position, mm: |

KamAZ, UralAZ, KRAZ, MAZ |

The crane-manipulator MKS-5531L (forest) is used for carrying out vantagement, harvesting and other operations on logging, transport and warehouse robots in forest industry enterprises.

When completing the collection, scrap materials can be used for the purpose of vantagement and dismantling of metal scraps.

Technical characteristics of MKS-5531L:

|

Strila |

|

|

Vantage capacity at 7.8 m, t |

|

|

Hook lift height, m |

|

|

Working vice, MPa |

|

|

Corner of a turn, hail |

|

|

Base of wine supports, m |

|

|

Installation options |

Behind the cabin, behind the vantage platform |

|

Basic chassis |

KamAZ, UralAZ, KRAZ, MAZ |

The crane is equipped with a rotator and clamp disposal.

On the basis of the serial MKS-5531A crane-manipulator, the PMKS-5531A automotive hydraulic trolley with a flexible cradle with a lifting capacity of 300 kg is produced.

Hoist PMKS-5531A is used for the mechanization of lifting and dismantling robots with various hanging equipment, as well as installation and dismantling robots to ensure the safety of people with tools at a height of up to 12 m.

|

Strila |

|

|

Vityag PMKS-5531A is based on MAZ, KamAZ, Ural, KrAZ vehicles. |

|

|

on villiot 1.83 m |

|

|

at 4.5 m |

|

|

on villiot 7.8 m |

|

|

Vantage capacity of the cradle, kg |

|

|

Height of the cradle, m |

|

|

Cradle size, m |

|

|

Working vice, MPa |

|

|

Turn around, hail |

|

|

Base of wine supports, m |

|

|

Masa of the anatomical organ, t |

|

The MKS-6531 manipulator crane is used for self-installation and self-installation of the base vehicle and the vehicle attached to it.

Technical characteristics of the crane-manipulator MKS-6531:

|

Strila |

|

|

Vityag PMKS-5531A is based on MAZ, KamAZ, Ural, KrAZ vehicles. |

|

|

on villiot 1.83 m |

|

|

at 4.5 m |

|

|

on villiot 7.8 m |

|

|

on villiot 11.8 m with subjug |

|

|

Maximum height of the hook lift, m: |

|

|

with the main line |

|

|

s podovzhuvachem |

|

|

Working vice, MPa |

|

|

Turn of the arrow in plan, degrees |

|

|

Base of wine supports, m |

|

|

Masa of the anatomical organ, t |

|

|

Overall dimensions (depth x width x height), mm |

2500 x 1100x2650 |

|

Installation options |

behind the cabin, |

|

behind the vantage platform |

|

|

Overall dimensions in transport position, mm: |

KamAZ, Ural, KrAZ, MAZ |

|

Є collection of vantage-spitting organs. |

|

JSC "INMAN" (Republic of Bashkortostan) serially produces hydraulic manipulators that can be used for installation of vantage-removal, construction-assembly and transport robots, such models:

IM20 with a maximum pull-out moment of 18.5 kN m, a line lift of 3.57 m, a pull-up capacity of 1.24 t, Z-shaped folding.

Mounted on the following types of vehicle chassis: Ural, ZIL, GAZ and others;

IM50 with a maximum pull-out moment of 52 kN m, a line lift of 7.1 m, a pull-out capacity of 2 t, Z-shaped folding.

Mounted on the following types of vehicle chassis: Ural 4320-1922, Ural 44202, KamAZ 43101, KamAZ 53221;

IM150 with a maximum pull-out moment of 132 kN m, a line lift of up to 13 m, a pull-up capacity of 4.2 t, Z-shaped folding.

Mounted on the following types of vehicle chassis: Ural, KamAZ, KrAZ;

IFZOOS with a maximum thrust moment of 317 kN m, a line lift of 8.1 m, a thrust capacity of 9 tons. Mounted on the following types of vehicle chassis: KrAZ 260G, KrAZ 260V, KrAZ 63221, KrAZ 6446 , Ural 43, Ural 43.

Technical productivity of transport means, t/year, de Q – vantage point, t;

| k g - coefficient of victory for vantage point; | 2,27 (3,8) |

| 8,75 (8,9) | |

| Basic chassis | k pr - coefficient of mileage; |

| k y - coefficient that the insurer spends an hour on cleaning and galvanizing; | |

| 7,4 | |

| 5,4 | |

| 1,08 (1,25) | |

| l – transportation distance, km; | |

| v – road speed, km/year; | t з, t r, t m - the most common hour of attraction, expansion and maneuvering, p. |

| MKS-4032 (BAKM-890) | |

| Purpose: | |

| manipulator crane MKS-4032 (BAKM-890) for self-handling, self-handling and transportation of emergency goods. |

Maximum vantage capacity of the main lift (at volute), t/(m):

Technical productivity of transport means, t/year, crane-manipulator "Signogorets-110" is used for self-handling, self-handling and transportation of emergency goods.

Main technical characteristics:

| Vantage capacity of the main lift is maximum (with tilt), t/(m) | 2,0 (4,5) |

| Maximum thrust moment, tm | |

| Basic chassis | Ural-4320 |

| k y - coefficient that the insurer spends an hour on cleaning and galvanizing; | telescopic articulated boom |

| Height of the lifting hook from the vehicle frame with the main boom, m | 8,8 |

| Vilit with the main arrow, m: | 6,6 |

| Overall dimensions in transport position, mm: width height | |

| maximum fluidity Ruhu, km/year | |

| Masa vantazhopіdomnogo annex, t | 2,1 |

| l – transportation distance, km; | |

| v – road speed, km/year; | VAT "Uralterminalmash", m. Mias |

| Rozrobki and Virobnitstva Camp | serial since 2002 |

Crane manipulator for industrial and technical purposes

MKS-5531

Technical productivity of transport means, t/year, The MKS-5531 manipulator crane is used for self-handling, self-handling and transportation of emergency goods.

Main technical characteristics:

| 2,3 (4,5) | |

| Maximum thrust moment, tm | 10,35 |

| Basic chassis | KamAZ-53212 |

| k y - coefficient that the insurer spends an hour on cleaning and galvanizing; | telescopic articulated boom |

| Height of the lifting hook from the vehicle frame with the main boom, m | 10,0 |

| Vilit with the main arrow, m | 7,8 |

| Overall dimensions in transport position, mm: width height | |

| Maximum speed of the rukh, km/year. | |

| Masa vantazhopіdomnogo annex, t | 1,85 |

| l – transportation distance, km; | |

| v – road speed, km/year; | BAT "KRAST" m. Stavropol |

| Rozrobki and Virobnitstva Camp | serial since 1992 |

Crane-manipulator BAKM-1600-2

Technical productivity of transport means, t/year, The BAKM-166-2 crane-manipulator is used for self-handling, self-handling and transportation of emergency goods.

Main technical characteristics:

| Vantage capacity of the main lift is maximum (with tilt), t/(m) | 3,5 (4,4) |

| Maximum torque | 15,4 |

| Basic chassis | Ural-4320 |

| k y - coefficient that the insurer spends an hour on cleaning and galvanizing; | telescopic articulated boom |

| Height of the lifting hook from the vehicle frame with the main boom, m: | 9,3 |

| Vilit with the main arrow, m: | 7,6 |

| Overall dimensions in transport position, mm: width height | |

| Maximum speed of the rukh, km/year. | |

| Masa vantazhopіdomnogo annex, t | 2,3 |

| l – transportation distance, km; | |

| v – road speed, km/year; | JSC "BAKM" m. Balashikha |

| Rozrobki and Virobnitstva Camp | serial since 1999 |

2.2.2 Avtovantazhuvachi

Designation DP-1604

Technical productivity of transport means, t/year, diesel vanator DP-1604 is used for moving and laying vanities in open areas and in closed areas: at bases, warehouses, salvage cars and other places with hard and durable surfaces.

Main technical characteristics:

Autonavantazhuvach fork virobnicho-technical

Designation VP-05

Technical productivity of transport means, t/year, diesel vanator VP-05 is used for moving and laying vanities on open platforms and other places with hard and smooth surfaces.

Main technical characteristics:

Technical characteristics of the crane-manipulator BAKM-890 (MKS-4032).

Table 6.4

|

Manipulator cranes are also produced by AT Inman (Bashkortostan). |

||

|

Vlasna mass KMU, kg |

Basic car |

|

|

Table 2. Technical characteristics of crane-manipulators BAKM 890 (MKS-4032) |

||

|

Maximum retracting moment, kN*m |

||

|

Maximum capacity, t: |

||

|

Table 1. Technical characteristics of crane-manipulators BAKM 460 |

||

|

Parameters |

||

|

BAKM 460-1 |

||

|

BAKM 460-2 |

||

|

two-section |

||

|

trisection |

||

|

Number of hydraulic telescope sections of the line |

||

|

Maximum pulling moment, kN m |

||

|

with mechanical cushions |

||

|

Main |

||

|

Lifting height, m: |

||

|

with a mechanical rubber band |

||

|

main line |

||

|

boom with mechanical guards |

||

|

Colony wrapping frequency, min-1 |

||

|

Maximum operating pressure of the hydraulic system, MPa |

Operation of the hydraulic system of the BAKM-890 crane

The operating distance of the pump 2 is to the sectional distributor 5, which contains hydraulic cylinders for blocking the springs 6 and hydraulic cylinders for lowering the bearing supports 7, 8, 9, 10. To turn off the lowering of the hydraulic cylinder values During the period of crane operation, the piston lines were filled with hydraulic oil.

The flow from pumps 2 and 3 reaches the same time as distributors 15 and 16. Distributor 15 controls the hydraulic cylinder for changing the pitch (cut) of line 27 and the hydraulic motor for turning 28 of the crane platform pulator.

The distributor 16 provides a hydrometer to the drive of the pulley winch 29 and the hydraulic cylinder after replacing the telescopic boom 23. The hydraulic cylinder increases the piston stroke and is mounted in the metal structure of the boom whether.

Section B of the distributor 15 and section A of the distributor 16 are equipped with additionally blocked distributors, in addition to which, during the period of switching on the main spool valves, galvanization of the vantage winch and platform is carried out, and during the switch-off period - Almation of these mechanisms with hydraulic cylinders 13 and 14.

The BAKM-890 crane-manipulator is equipped with safety devices that, in an emergency situation, turn on the electromagnets of hydraulic valves 17, 18 and 19. As a result of turning on the electromagnets, the hydraulic system is connected Otherwise, the control of the shut-off valves 20 and 21 with drainage hydraulic line requires the release of pumps 1 and 3. To change As the platform rotates smoothly, throttle 22 is adjusted using the vice regulator. - the principle of the hydraulic diagram of the BAKM-890 crane: 1. hydraulic tank;